Peptides are powerful biological molecules, possessing enormous potential in the biotechnology and healthcare sectors. Recently, recombinant peptide synthesis has emerged as a cutting-edge method of synthesizing peptides, significantly advancing the field of drug discovery. Because of their special characteristics, peptides have tremendous potential in a variety of biomedical applications, including medication delivery and tissue engineering, including the ability of forming diverse structures, biocompatibility, and tissue penetration capacity. Thus, recombinant peptides have become valuable targets for therapeutic uses such as recombinant peptide drugs. Creative Peptides offers an advanced service known as recombinant peptide synthesis. These recombinant peptides can be designed and synthesized to meet the custom specifications of our clients, ensuring that each peptide sequence is precise and fits the specific needs of their project.

Recombinant peptide is a manipulated form of peptide encoded by recombinant DNA, which has been cloned in a foreign expression system to supports the expression of the exogenous gene. This recombinant DNA construct can be used to manufacture large quantities of useful protein products. The recombinant DNA, usually the cDNA sequence of the target peptide, is designed to be under the control of a well-characterized promoter to express the target peptide within the chosen host cell to achieve high-level protein expression.

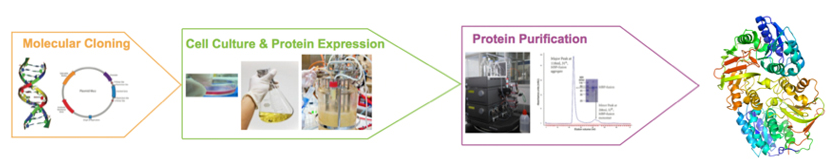

Recombinant peptide synthesis refers to the production of peptides, which are short chains of amino acids, through recombinant DNA technology. This is an area of biotechnology that involves the use of living organisms, such as bacteria or yeast, to produce desired proteins that may be difficult, expensive, or impractical to obtain in large quantities by other methods. Here is a general rundown of the process:

Fig. 1 Synthesis of recombinant peptide

Fig. 1 Synthesis of recombinant peptide

The process of producing targeted proteins from certain modified DNA templates is called recombinant peptide expression. Traditional methods of expression include transfecting cells with a DNA vector containing the template, then culturing the cells to make them transcribe and translate the demand protein. Other strategies are also applied, such as sonication, repeated freezing, thawing, homogenization by high pressure or grinding, or permeabilization via detergents or enzymes.

The benefits of producing proteins through designed DNA fragments are various. The risk of immune reaction is low and the the specific activity of proteins is high results from the clone and expression of human gene. Thus, the therapeutic protein is able to be produced with high effectiveness.

A practical and adaptable method for producing huge amounts of artificial and modified peptides, recombinant expression also makes it possible to produce isotopically tagged peptides and longer artificial peptides that resemble proteins at a low cost.

Peptides are complex biomolecules that are synthesized by bonding together amino acids. There are different techniques and processes used for the production of peptides, primarily syntheses in laboratories or recombinant techniques utilizing biological systems. Synthetic and recombinant peptides differ in various aspects including their production processes, cost, reliability, scalability, and purity.

Production Process: Synthetic peptides are produced through a chemical process known as solid-phase peptide synthesis (SPPS) or liquid-phase peptide synthesis (LPPS). Recombinant peptides, on the other hand, are produced in biological systems (bacteria, yeast, etc.) using genetic engineering.

Scalability: Recombinant technology allows for larger scale production of peptides which is particularly useful for industrial or clinical applications, compared to traditional synthetic methods.

Complex Structure: Some peptides have complex structures and modifications that cannot be synthesized chemically, but can be produced through recombinant methods.

Applicable Length: Chemical synthesis is more suitable for short to medium-length peptides, while recombinant expression can be used to produce longer peptides and complete protein.

Cost: While the cost varies based on factors like scale and complexity, generally, synthetic peptide production can be more cost-effective for short sequences of up to 20-30 amino acids. For larger peptides and proteins, recombinant production may be a more affordable option.

Post-Modification Ability: Recombinant expression can undergo complex post-translation modification in eukaryotic system, but chemically synthesized peptides usually do not have this modification ability.

Time: It is often faster to produce large quantities of recombinant peptides than it would be to synthesize the same quantities.

Yield: Recombinant peptides generally have a higher yield than synthetic peptides. The synthetic peptide chemistry may have significant losses at each coupling and deprotection step, which gets multiplied very quickly with every additional amino acid residue.

Recombinant peptide synthesis can produce large quantities and long fragments of peptides more efficiently, and they have the intrinsic capacity to allow post-translational modifications, vital in many bioactive peptides. Recombinant peptides have ushered in a new era in protein-based therapeutics and biotechnology. By leveraging the power of genetic engineering and biotechnological advances, we are now able to produce peptides in large quantities and design novel therapeutic agents with greater potency and specificity. Through advanced methods of recombinant synthesis and the production of peptides, new doors have opened for peptide-based drug therapy. Though challenges persist, continual advancements promise exciting potential for the role of peptides in the future of personalized medicine.

Therapeutic peptides represent a rapidly expanding market within the pharmaceutical industry. Compared to traditional small molecule drugs, they have specificity and lower toxicity, and are becoming more and more popular for treating series of illnesses such as cancer, metabolic disorders, infectious diseases, and cardiovascular conditions. For instance, the active pharmacological elements of several recombinant peptide medications, such teriparatide and oxytocin, are created through chemical synthesis. Peptides can be altered in an infinite variety of ways thanks to their chemical production.

Existing recombinant peptide drugs include Insulin for the treatment of diabetes and Erythropoietin (EPO) for anemia linked to kidney disease. Besides, several recombinant peptide drugs have been applied to treat varied diseases such as multiple sclerosis and cancer. For example, A recombinant peptide drug named Copaxone (glatiramer acetate) is used for curing multiple sclerosis. These applications demonstrate the rapid development of recombinant technology in drug production and open the door for the creation of peptide-based medicines in the future.

A recombinant peptide therapy is another application supported by recombinang DNA technology. It refers to expressing specific peptides in bacterial or mammalian cells inserted with the DNA fragments encoding the peptides, and then purifying it from them.

Recombinant peptide therapy is used to treat a range of medical conditions, from diabetes and autoimmune diseases to cancers. The primary advantage of this therapy is that it can specifically target and modify cellular functions, leading to reduced side effects compared to traditional treatments. Examples of recombinant peptide therapy include recombinant insulin for the treatment of diabetes, and recombinant human growth hormone used to treat growth disorders in children.

As with all treatments, recombinant peptide therapy also has its challenges and risks. Some of these include potential immunogenic responses, meaning the body's immune system could recognize and attack the peptide, rendering the therapy ineffective. There could also be issues related to stability, delivery, and dosing of the peptide drug. Researchers are constantly working on new methods to enhance the potency, selectivity, and stability of peptides while reducing potential side effects.

As the world's largest producer of synthetic peptides, Creative Peptides not only provides the synthesizing of recombinant peptides, but also offers services for cloning, expression, and purification, providing a comprehensive solution for our clients' recombinant peptide synthesis needs. Giving utmost priority to quality, we ensure that the peptide synthesized meets the stringent standards. The services we provide have the following advantages:

Superior Precision: Creative Peptides' recombinant peptide technology provides custom peptides exactly as requested. Every step of peptide synthesis is subject to Creative Peptides' stringent quality control.

Excellent Procedure: Conventional chemical peptide synthesis has only limited abilities to synthesize long or complicated peptides, whereas our proprietary recombinant peptide technology can handle the toughest possible peptide sequences, of any length, on any scale.

Scalable System: In quantities of several milligrams up to 100 grams.

Low Cost: Our recombinant peptide package provides a confidential and efficient service at competitive prices for large-scale, long, and complicated peptide production.

Consistency: With fewer steps than conventional peptide synthesis, recombinant peptide technology produces synthetic peptides with high levels of consistency.

Recombinant peptide synthesis uses genetic engineering to produce peptides in biological systems like bacteria or yeast, offering higher scalability and the ability to produce longer or more complex peptides compared to traditional chemical synthesis methods.

Recombinant peptide synthesis enables the production of large quantities of peptides with complex structures and post-translational modifications. This method also ensures high consistency and can be more cost-effective for larger peptides and proteins.

Recombinant peptide synthesis is highly scalable, allowing for the production of peptides in larger quantities, which is ideal for industrial and research applications. In contrast, synthetic methods are often limited in scale and are more suitable for shorter peptides.

Yes, recombinant peptide synthesis can handle challenging peptide sequences, including those that require modifications or involve large, complex structures. This is a key benefit over traditional synthetic methods.

Recombinant peptides are widely used in biotechnology for applications such as enzyme production, diagnostic tools, vaccine development, and tissue engineering, thanks to their biocompatibility and ability to form complex structures.

The purity of recombinant peptides is ensured through rigorous quality control measures, including expression system optimization, purification techniques like chromatography, and proteolytic cleavage to isolate the desired peptide.

Challenges in recombinant peptide synthesis include optimizing expression systems for high yield, avoiding peptide aggregation, and ensuring the stability of the synthesized peptides. However, advancements in technology are continually addressing these issues.

References